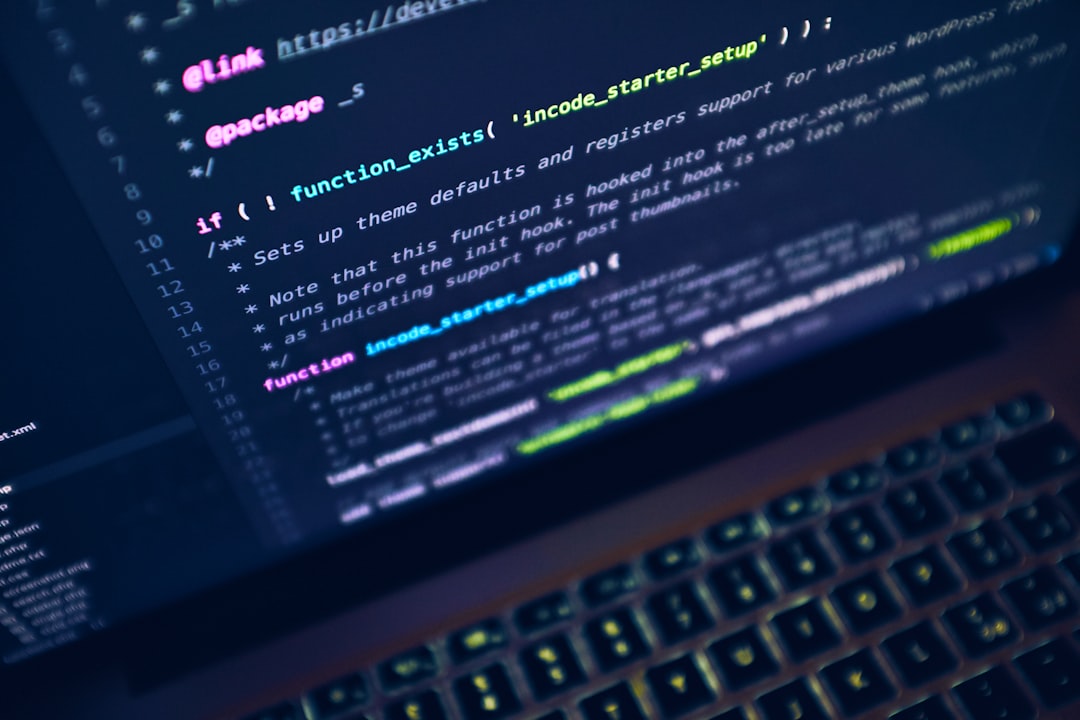

In the present time, the manufacturing processes are becoming complex and the transition from mass production to lean production sets to the manufacturer high standards of quality and reliability. As a consequence, the requirements for equipment reliability is getting higher. Therefore, it is becoming a difficult task to the plant workforce to choose an appropriate maintenance policy and spare parts strategy. In this case, properly constructed diagnostic system and system reliability calculation would be very useful for designers and plant managers to significantly reduce the number of unnecessary tests and hence reducing the associated costs. To achieve higher reliability and high quality of the products, the manufacturing companies should implement predictive and analytic algorithms by means of software and applying them to existing maintenance processes.